It’s been over 30 years since Chuck Hull invented the first 3D printer in 1983. Ever since then, the idea of machine-printing objects from scratch has gone from fiction to reality, opening up new opportunities for every field from science to art.

3D printing may not be quite there yet, but in three decades the technology has progressed leaps and bounds in terms of the scope and utility of 3D-printed objects. Surprise, surprise: It’s not just gimmicks and toys.

It’s easy to be skeptical of 3D printing, which is still slower, more expensive, and less effective than traditional manufacturing. But by focusing only on the technology’s few remaining shortcomings, we fail to observe how far 3D printing has already come.

Here are 10 of the most incredible objects that can already be 3D printed with today’s technology.

Body Parts

Ears, kidneys, blood vessels, skin and bones have all been successfully 3D printed by scientists around the U.S. Instead of the typical plastic normally associated with 3D printing, these 3D medical “bioprinters” use a gel-like substance made from cells. (The outlier is bones, which use a ceramic powder instead.)

Advances in 3D bioprinting mean that some day soon, doctors will be able to provide every patient with a perfectly matching bone fragment, skin graft, or kidney (3D printed kidneys exist, but they are not yet functional).

And until 3D bioprinting gets around to printing whole human limbs, 3D plastic printers are already capable of printing artificial limbs for less than $100 in just a few hours.

Pizza

This NASA-funded 3D printing project is good enough to eat. The organization began funding 3D-printed food in order to feed astronauts in space.

Usually, a 3D printer works from just one material cartridge. But the pizza printer works by printing from multiple cartridges at once, containing material like dough, cheese, or sauce.

You can watch the entire process on YouTube:

Chocolate

Replace the typical plastic in a 3D printer’s cartridge with melted chocolate and the possibilities for futuristic desserts are endless. You can print any writing or drawing that can be processed by a computer, and it’ll be edible.

Chocedge is one of the first chocolate-exclusive 3D printers, at several thousand dollars a pop. But there’s a surprisingly large amount of competition in the field of 3D-printed candy. In January, the Hershey Company and 3D Systems announced a partnership to create all kinds of 3D printed confections. If the company replaces factory workers with 3D printers, it might be able to streamline its process while giving us slightly more futuristic Hershey’s Kisses.

Clothing

3D printed clothing may not be in stores yet, but it’s already debuted on the runway. Model Dita Von Teese wore the first fully articulated 3D printed gown—made especially to fit her. With nearly 3,000 joints, the dress flows according to her curves.

For regular people, 3D-printed clothing could mean a level of customization beyond the abilities of any tailor—clothing literally printed to any body’s specifications. Though unless you’ve got a figure like Dita’s, you might not be just ready for that yet.

Musical Instruments

It’s now possible to create functional musical instruments wholly or partly out of 3D-printed objects. Commercially, there’s the Odd 3D printed guitar, which promises a unique look as well as premier acoustics. MIT Media Lab researcher Amit Zoran was able to print a working flute. German firm EOS printed a polymer-based violin.

The only problem? 3D printed instruments don’t sound very good yet, at least not compared to traditional instruments. Violin soloist Joanna Wronko demoed a standard violin and the 3D printed one side by side at TED Amsterdam, and it’s clear which one audiences preferred.

Cars

Urbee 2 looks more like a jelly bean than a car. But it’s actually the first vehicle in existence that has been manufactured chiefly from 3D-printed parts.

This three-wheeled car is cheaper and more fuel efficient than just about any vehicle on the market today, but its 23 horsepower engine (with batteries combined) means it could struggle to reach top highway speeds.

Urbee 2’s inventors aspire to drive the 3D-printed vehicle across the U.S. within the next two years, but they’ll need to do some work first. Right now, the car is nowhere near compliant with the U.S. highway code.

Guns

Possibly the most controversial creation you can build with a 3D printer is a firearm. The first model was called the Liberator, developed by 26-year-old Cody Wilson.

Now, anybody who has a 3D printer and an Internet connection can download and print their own gun out of plastic parts. But just because they’re made of plastic doesn’t mean they’re not deadly—according to the FBI, the Liberator fires bullets capable of piercing internal organs.

Although the gun exploded when the FBI tried to print its own copy of The Liberator to test it, Wilson uploaded a video of himself firing it successfully. Just how long 3D printed guns will be legal, however, is hard to tell, as local legislatures work to ban them.

Drones

One disruptive technology begets another when 3D-printed drones roam the skies.

Researchers at Southhampton University have developed the SULSA (Southampton University Laser Sintered Aircraft), an unmanned aerial vehicle that can be mass produced through 3D printing. It has a top speed of 90 miles per hour, and can remain in the air for a total of 30 minutes.

The drone can be assembled from plastic parts in 10 minutes, without the use of screws or other conventional fasteners. As a result, it is virtually silent in cruise mode. You’ll never see this 3D printed drone coming.

Adult Products

Of course, one of the first things people figured out with 3D printers was how to make something sexy. The adult industry has already harnessed the technology to print dildos, vibrator sleeves, and other accessories. Some are heavily customized(link NSFW): 3DEA, a popup shop in Chelsea, is providing toys for customers tailored to personal scans. .

At this point it’s predictable that the next step in human progress would involve sex. Perhaps this is a sign that 3D printing really has potential—after all, we can’t forget what people first began using the Internet for.

3D Printers

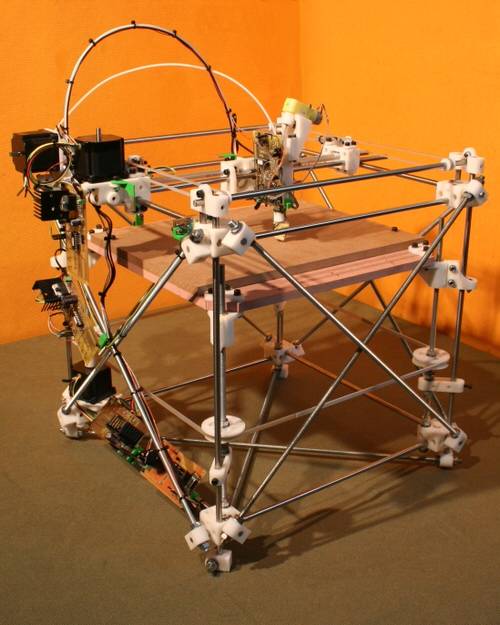

Yes, you can even print 3D printers with a 3D printer.

With the advent of a 3D printer capable of printing itself, we’ve gone full circle. The RepRap is an open source printer that does just that. The RepRap is released under a free software license, so you can freely print and put together all the parts that make it up. Just buy the machine (for $500-$600 online), and program it to self replicate until you’ve made 3D printers for all of your friends.

What have I missed? List your favorite 3D prints in the comments.

Photos by Subhashish Panigrahi, Albert Sanchez, 3dilla, Southampton University, and RepRap.